Iron in your irrigation water: why lab results may not always tell the entire story

July 7, 2014 in Articles

Pete Landschoot, Prof. Turfgrass Science, Dept. Plant Science, Penn State

In conducting a golf course irrigation water quality survey, I recently came across a water sample pumped from a deep well that showed a strong red-brown cast. The color of the water indicates a high iron concentration, which may be of concern to the superintendent with respect to negative effects on the irrigation system and other cosmetic problems. Although I was quite certain there was a high amount of iron in the sample, the lab results indicated below-normal levels of iron (<0.01 ppm).

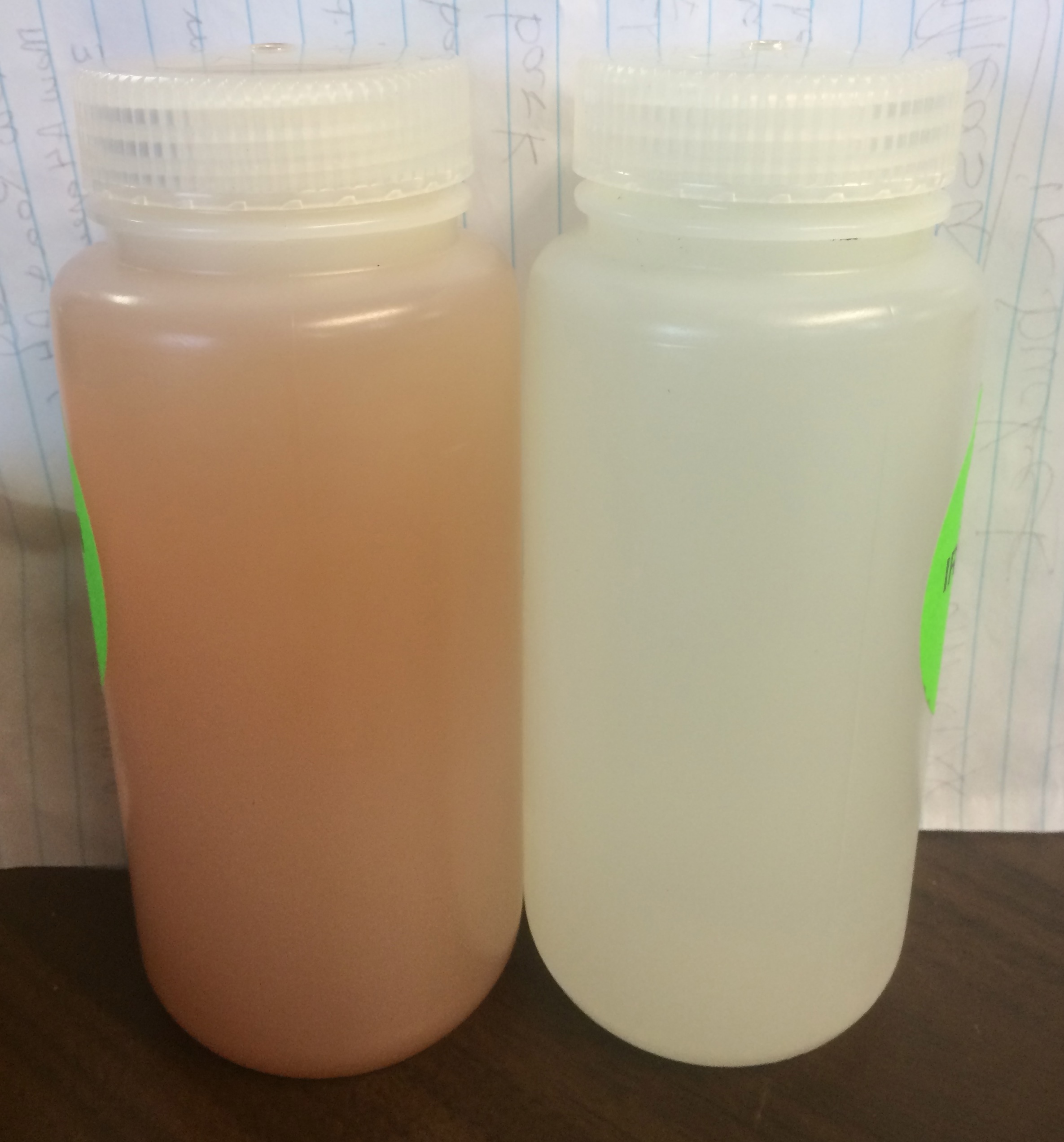

Fig. 1. Two irrigation water samples from golf courses in northern PA; the sample on the left (LM-1) shows a reddish-brown tint, whereas, the sample on right (CO-1) is clear and colorless.

So why didn’t the lab detect high iron levels in a sample that looked like it was loaded with iron? The answer involves an understanding of the different forms of iron in water, and how labs test irrigation water.

Iron is a common metallic element found in soil and rocks in the earth’s crust. As water percolates through soil and bedrock, it dissolves iron-containing minerals and allows them to go into solution. Under anaerobic conditions, such as in deep wells, bore holes, or lakes/ponds that do not turn over (circulate) rapidly, iron exits in the dissolved or soluble form (dissolved iron is often referred to as ferrous iron and designated as Fe+2). Water containing soluble ferrous iron tends to be clear, but turns cloudy when exposed to air. As water becomes increasingly aerated, the iron is oxidized to the less soluble ferric state (Fe+3), and turns a red-brown or rust color. Some or most of the iron will eventually precipitate out of solution as iron oxide (Fe2OH3), and will sink or remain suspended, leaving the water with a red-brown cast.

The pH of your irrigation water also influences iron reactions. Iron exists in the dissolved state in very acidic water, and becomes insoluble and precipitates as the pH of irrigation water increases and becomes more basic.

Because aeration and pH influence the solubility of iron in irrigation water, it’s no wonder that lab results can be somewhat confusing. When a water sample is sent to a lab, the water is often filtered and analyzed without adjusting the pH. This makes sense because you want to know what’s in your water and how it will influence soils and plants at its normal pH. If your pH is near neutral or basic, most of the iron will not be in the dissolved state; and thus, will not be detected by some types of analytical equipment. However, by analyzing water under very acidic conditions (pH <2.0), most of the iron will revert to the dissolved form and be detected by analytical equipment.

In the case of the reddish-brown water sample mentioned in the beginning of this article, the pH of the water was 7.1 and the iron content was reported as <0.10 ppm. This is well below the upper limit value of 5 ppm suggested in textbooks and on water test reports. With assistance from Penn State’s Agricultural Analytical Services Lab (ASSL) Director, Dr. John Spargo, we did some further testing of this sample to see why the iron content was so low. When the water was unfiltered and acidified to a pH of about 2.0 (according to ASSL’s drinking water test procedures), the iron concentration detected was 48.5 ppm, a significant increase over the original reported value. Based on these results, we suspect almost all the iron in the water was precipitated or suspended as iron oxide.

So, if you want to know the total iron (dissolved and non-dissolved) in your irrigation water, make sure you check with the lab to see if they can analyze the sample accordingly (unfiltered and acidified).

Table 1. Results of iron concentrations from two methods of analyzing irrigation water for two different irrigation water samples. The first procedure involved forcing each sample through a 1 µm filter and analyzing at the existing pH (7.1). The second procedure involved no filtering, and acidification of the water with 1% HNO3, resulting in a pH of around 2.0.

| Sample | Test Procedure |

Iron (ppm) |

|||

| LM-1 | Filtered 1 µm, not acidified (pH 7.1) |

<0.1 |

|||

| Not filtered, acidified, 1% HNO3* |

48.5 |

||||

| CO-1 | Filtered 1 µm, not acidified (pH 7.1) |

1.4 |

|||

| Not filtered, acidified, 1% HNO3* |

4.2 |

||||

| *Standard procedure for drinking water samples when turbidity is <1 Nephelometric Turbidity Units | |||||

Problems associated with excess iron in irrigation water:

Although many labs consider >5 ppm of iron undesirable in irrigation water, this does not mean it will harm your plants and soil. In fact, turf and soil problems due to high iron concentrations in water are rare. Potential problems due to high iron in irrigation water mostly center around staining of concrete surfaces; plugging of irrigation equipment and drainage tile; as well as unsightly deposits of rust-colored material on ornamental plants. High iron concentrations in spray tank water can clog screens and nozzles, and negatively affect performance of some pesticides. If concentrations are exceptionally high, and iron-laden water is used frequently and continuously, some nutrient deficiencies may result.

Fig. 2. Deposit of iron oxide material extracted from clogged drainage tile from a golf course in western PA.

Another common problem associated with high iron concentrations is biofouling. Biofouling is a result of proliferation of bacteria under low oxygen or anaerobic conditions. The stringy, bacterial slime can coat intake screens, reduce pumping efficiency, and cause unpleasant odors. Biofouling can be associated with stagnant ponds and deep wells with low oxygen levels.

Treatment of water with high iron concentrations:

Treatment of irrigation water containing excess iron involves precipitating the dissolved iron before it reaches your irrigation system. This can be accomplished by oxidizing iron via aeration, and/or raising the pH of your reservoir to at least 7.2 with hydrated lime or running water over a bed of crushed limestone. Filtration is sometimes required to prevent clogging of irrigation equipment if precipitated iron does not settle to the bottom of the reservoir and is taken in to the irrigation lines.

References:

Duncan, R.R., R.N. Carrow, and M.T. Huck. 2009. Turfgrass and landscape irrigation water quality: Assessment and management. CRC Press, Taylor and Francis Group. 464 pp.

Obreza, T., E. Hanlon, and M. Zekri. Dealing with iron and other micro-irrigation plugging problems. Univ. of Florida IFAS publication SL 265.

Oram, B. 2014. Iron and manganese in water: A common problem in Northeast Pennsylvania. Water Research Center. http://www.water-research.net/index.php/iron

Zinati, G. and X. Shuai. 2005. Management of iron in irrigation water. Rutgers Cooperative Research and

Extension Fact Sheet, FS516.